The spacing between the holes is shown for most of them, although the diameter is not. The numbers adjacent to the hole refer to the firing sequence. Sometimes, a few angled holes are placed within the burn, but this shouldn’t be confused with the other major type of cut, i.e., the angled cut. The unloaded holes within the burn are referred to as relief holes. The burn cut consists of parallel holes, sometimes of different diameters, and always some of the holes are unloaded. Its use quickly spread to many underground mines. Burn is the shortened name for the Viburnum Cut so-named because it was developed for use in the lead-zinc mines found in the Viburnum trend in Missouri, back in the 1950s. The most common type of parallel cut is known as the burn cut.

There are two general types of cuts: parallel cuts and angled cuts.

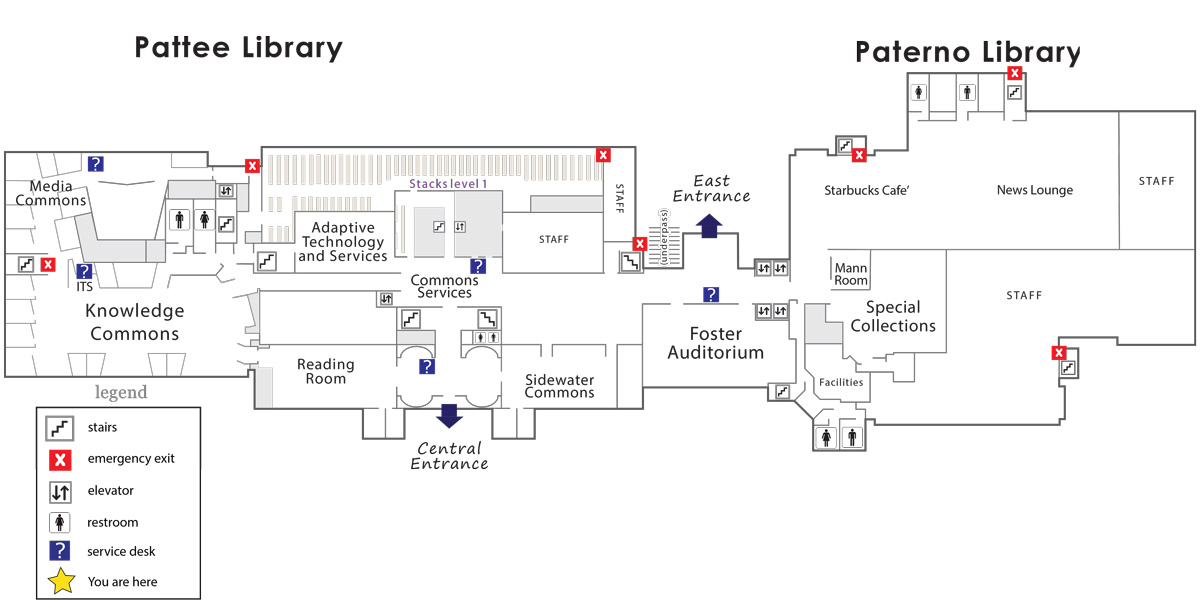

PATTERNO LIBRARY PSU FREE

The purpose of the Cut is to create a second free face, which we introduced in the last section of this lesson. This can be applied to cross-sections of almost any size and shape.

Notice that the cross-section is divided into named regions. The cross-section shown here is typical, but regardless, the content that we are going to cover applies to other shapes as well. The strength of the rock and the expected life of a particular opening will influence the shape as well as the dimensions of the opening. Rectangular openings have sharp corners that tend to concentrate stresses, whereas elliptical or circular openings do a better job distributing the stress around the opening, and as such, they are more stable. These requirements may be openings of a minimum height and width to allow equipment access, or the dimensions may be based on production requirements. If we are driving headings that will be used by people and equipment to access the ore and conduct the mining operation, we will strive to create openings that will be stable over time, and be of dimensions that meet certain requirements. The overall pattern will be based on the desired shape of the blasted opening.

0 kommentar(er)

0 kommentar(er)